|

CRUISING SPEEDS*

Full power 75% power 65% power 55% power |

(ktas / kph) 285 / 527 261 / 483 245 / 453 225 / 416 |

|

*All Speeds are at Mid-Cruise

Weight |

|

|

ENGINE Manufacturer Model Rating (hp @ rpm) Number of Cylinders Recommended TBO (hrs.) |

Lycoming TIO-540-U2A, IO-540-S1A5(MM)*, or IO-540-AA1A5(MM)* 350 @ 2500 6 1800 |

|

*Machen Modified Engine Used on

Superstar 700 Top of Page |

|

|

PROPELLERS Manufacturer Number of Blades Type Diameter (in. /cm.) |

Hartzell 3 Constant Speed, Full Feathering 72/183 |

|

WEIGHTS Max. Ramp Weight Max. Takeoff Weight Max. Landing Weight Average Empty Weight* Average Useful Load |

(lb / kg) 6356 / 2883 6315 / 2864 6000 / 2722 4656 / 2112 1700 / 771 |

|

*Includes Unusable Fuel, Full

Oil, and Full Operating Fluids Top of Page |

|

|

EXTERIOR

DIMENSIONS Wing Span Length Height Wheel Tread Wheel Base CABIN DIMENSIONS Length Width Height Headroom (Seat to Ceiling) Front Seat Middle Seats Rear Seat Baggage Door Cabin Door Top of Page |

(ft / m) 36.7 / 11.2 34.8 / 10.6 13.2 / 4.1 10.2 / 3.1 11.7 / 3.6 (in / cm) 141.5 / 359 45.5 / 115 46.5 / 118 35.0 / 88 33.5 / 85 33.5 / 85 22 x 24 / 55 x 60 28 x 45 / 71 x 114 |

|

BAGGAGE Volume (cubic ft / m) Capacity (lb / kg) Vol. w/Aux. Fuel (cubic ft / m) |

30 / .85 240 / 108.9 20 / .57 |

|

FUEL & OIL

CAPACITY Usable Fuel w/Std Tanks (gal/l) Usable Fuel w/Aux. Fuel (gal/l) Oil (qt/l) Top of Page |

165.5 / 626.5 210.5 / 796.7 12 / 11.4 |

|

RATE OF CLIMB*

Two Engine Single Engine |

(fpm / mpm) 1875 / 572 383 / 117 |

|

*At Sea Level and Gross Weight

|

|

|

STALL SPEEDS

Flaps Down Full 45° Flaps Up |

(ktcs / kph) 73 / 136 81 / 151 |

|

Top of Page |

|

|

CRUISE RANGE*

75% power 65% power 55% power |

(nm / km) 958 / 1775 1000 / 1852 1100 / 2038 |

|

*For 210.5 Gallons Usable (796.7

Liters). Includes Allowance for Fuel Used During Start, Taxi, Takeoff,

Climb, Descent, and a 45 Minute Reserve at Economy Fuel Mixture |

|

|

TAKEOFF DISTANCE*

Ground Run Total Distance over 50 ft Obstacle |

(ft / m) 1950 / 595 3080 / 940 |

|

*Sea Level, Zero Wind, Standard

Temperature, Gross Weight Top of Page |

|

|

SERVICE CEILING*

Two Engines (100 fpm) Single Engine (50 fpm) |

(ft / m) 30,000+ / 9,000+ 16,000 / 4,877 |

|

*6000 lb, Standard Temperature

|

|

|

PRESSURIZATION

Standard Optional |

(psid) 4.25 5.50 |

|

|

|

|

LANDING DISTANCE*

Ground Roll Total Distance over 50 ft. Obstacle |

(ft / m) 1440 / 439 2140 / 652 |

|

*Sea Level, Zero Wind, Standard Temperature

Top of Page |

|

| Airframe Cost 1982 602P | $ 260,000.00 | |||||||||

| Airframe Restoration | $ 125,000.00 | |||||||||

| New Super 700CR w/ Factory OH 350 HP Engines | $ 156,324.00 | |||||||||

| New 5.5 PSI Cabin Pressurization w/ Electric Components and FL300 Certification | $ 29,500.00 | |||||||||

| New KFC-225FD Auto-Pilot w/ Alt./Rate Preselect | $ 45,000.00 | |||||||||

| New Garmin Avionics Package w/ 340

Intercom, 530 Nav 1, Comm 1, GPS 1, 430 Nav 2, Comm 2, GPS 2, Dual 327 Transponders |

$ 45,000.00 | |||||||||

| New Electric Windshield Anti-Ice | $ 8,220.00 | |||||||||

| New De-Icer Boots, Known Icing Certification | $ 15,500.00 | |||||||||

| New Inconel Front Exhaust and Tailpipes | $ 13,940.00 | |||||||||

| $ 10,580.00 | ||||||||||

| $ 5,680.00 | ||||||||||

| $ 4,460.00 | ||||||||||

| $ 2,330.00 | ||||||||||

| $ 2,030.00 | ||||||||||

| $ 2,030.00 | ||||||||||

| $ 1,580.00 | ||||||||||

| $ 3,062.00 | ||||||||||

| $ 1,275.00 | ||||||||||

| $ 1,155.00 | ||||||||||

| $ 1,855.00 | ||||||||||

| $ 625.00 | ||||||||||

| $ 5,230.00 | ||||||||||

| $ 819.00 | ||||||||||

| $ 2,042.00 | ||||||||||

| New Metal Instrument Panels and Overlays | $ 4,500.00 | |||||||||

| New Paint | $ 17,000.00 | |||||||||

| New Leather Interior | $ 12,000.00 | |||||||||

| New Pull-Down Shades | $ 10,000.00 | |||||||||

| Updated Overhead Duct | $ 3,500.00 | |||||||||

| New Propeller Hubs | $ 6,000.00 | |||||||||

| New Wing Pneumatic Regulators | $ 3,000.00 | |||||||||

| New Pneumatic Pumps | $ 3,000.00 | |||||||||

| New Hydraulic Pump | $ 1,500.00 | |||||||||

| Overhauled Propeller Governors | $ 1,500.00 | |||||||||

| Overhauled Main and Nose Gear - All

New Engine Baffling, Turbo Brakets, and Blankets |

$ 3,900.00 | |||||||||

| JPI EGT, CHT, TIT, Fuel Flow Engine Monitor System | $ 8,500.00 | |||||||||

| REPLACEMENT VALUE | 817,637.00 | |||||||||

Aerostar Aircraft Corporation was formed

in 1991 by its principals, Steve Speer and Jim Christy.

Aerostar Aircraft Corporation is planning in the future to produce both a Jet

and a Turboprop version of the Aerostar.

Before co-founding Aerostar Aircraft Corporation, Mr. Speer held engineering

positions with Ted Smith Aerostar, Boeing Company, Aerojet Manufacturing

Company, and the Navy's Pacific Missile Range.

Before co-founding Aerostar Aircraft Corporation, Mr. Christy held positions in

customer service, sales, and sales management with Ted Smith Aerostar

Corporation, Piper, and with Aerostar dealers.

Aerostar Designer . . . AVIATION LEGEND

The Aerostar series of aircraft was originally conceived by Ted R. Smith, one of

the most brilliant aircraft designers of all time.

Arguably, no one has had as great an impact on general/business aviation as Ted

Smith. Each aircraft design credited to his name helped set new standards for

future designs. It is not widely known, but Mr. Smith designed, certified, and

built the first all new small twin engine business aircraft, the Aero Commander.

He then brought the first small business jet aircraft to market which was the

Jet Commander now evolved into the Astra Jet. Mr. Smith, more designer than

promoter, was know as the "quiet man", letting his revolutionary aircraft

designs, with their spectacular performance, speak for themselves.

The Aerostar family of aircraft was the culmination of 40 years aviation

experience and expertise, and included the design concepts and engineering.

HISTORY

The design work for the Aerostar was begun by the Ted Smith Aircraft Company in

November 1964, with the first model 600/601 prototype flying in October 1967.

Certification was in March 1968 for the 600 and November 1968 for the 601.

Additionally, two more certificates were obtained. These were for the use of

180-hp and 200-hp engines, called the Models 360 and 400 respectively. After

certification, controlling interest in the company was sold to American Cement.

In 1970 American Cement sold the firm to Butler Aviation, but little was done

until 1973, when Smith resumed control and started production in Santa Maria,

California, on both the normally aspirated 600A and the turbo 601A.

On August 6, 1975, and Aerostar 601A, piloted by Jack Chrysler, set a class C1d,

2000-kilometer, closed-circuit speed record for piston-powered land-planes at

237.08 knots (272.83 mph). Between November 4 and 9, 1977, an Aerostar 601P

piloted by Philander Claxton III and Jack Cink recorded a new round-the-world

speed record for piston-engine aircraft. The 19,974-n.m. (23,000-s.m.) trip was

completed in 104 hours, 5 minutes and 30 seconds, averaging 190.91 knots (219.70

mph).

In 1976 Smith died, and Piper Aircraft soon took over the Aerostar line,

eventually moving production to Vero Beach, Florida. On February 14, 1981, Piper

announced the Model 602P and named it the Sequoia. This pressurized plane had

Avco Lycoming IO-540-AA1A5 low-compression engines with integral turbochargers.

The name was later withdrawn.

The Design Concept

In an address to the Aerostar Owners Association in 1971, Smith detailed the

reasoning behind the Aerostar. The following data garnered from the speech's

transcript:

Smith had been with Douglas Aircraft and designed the A-20, a low-level attack

bomber for the military in World War II. Later he designed the Aero Commander

twins for the civilian market. In 1963, when Rockwell decided not to pursue any

new development other then the Jet Commander, Smith took six months off to mull

over his future. He said that while skiing the slopes of the Lake Tahoe area, he

would develop concepts of a new plane and then put them on paper at night. The

result was the Aerostar.

Part of Smith's concept was commonality and a reduction in parts. Commonality

was achieved by the use of the same parts for the rudder and elevator, and the

horizontal and vertical stabilizers. This was a first for the industry.

Simplicity and production design were also a major effort. But there was a goal

other than just a simpler airplane. Smith wanted the plane to be adaptable to a

range of power sources, from a single-engine to "a pure turbine-powered, 500-mph

airplane." His idea was to put as much of the heavy and beefy equipment on the

outside to use it for structural strength. One such way was the elimination of

many pieces of under-structure and substitution of heavier-gauge skins (0.050

inches, twice the normal wing-skin thickness). This made the skin carry more of

the bending, torsion and shear loads. Smith said there are 50 percent fewer

model-specific parts in the Aerostar than in competitive types.

These understructure alternations and heavier skins gave the plane a rigid

structure that directly relates to a high dynamic factor. Smith said that as

such, the plane, as it's built, can be flown at true airspeeds of 800 mph

without getting into the flutter parameters. He also said the plane has been

flown at altitude, with power and in a slight decent, at 500 mph true.

Statically, the plane was tested to 6000 pounds gross and an ultimate load

factor of 6 Gs with no deformations, no permanent sets, no cracks and no

failures of any kind. Additionally, the load was held for an indefinite period

of time at this ultimate load factor. The FAA requires a hold of five seconds,

but "...since nothing was happening, we just kept the load on for an indefinite

period of time, then relieved the load, and the airplane came back to its normal

status as it was before the load was first applied." He also said that strain

tests showed the plane could double its gross weight with nothing more than

minimal structural changes.

The Question of Stability

Before we get too far along, let's address the issue of the plane's reputation.

As with all planes and people, there will be stories about the good and bad

points. When I mentioned to some friends that we were going to do this story, I

was regaled with stories about the plane falling out of the sky. Asking Jim

Christy, Aerostar's vice president, about this, he said the story originated

with stall tests. A test pilot took the plane and ran a series of stalls,

involving 90 percent power and the plane in a dirty configuration. At about 64

knots, which is way below Vmc, the plane's wing was flying, but the rudder lost

effectiveness. The next things to go were the ailerons, but the wing was still

flying - just the opposite of what's desirable.

The solutions are many and varied, plus too long and technical for this article.

Over the years, Machen Inc., a company that still specializes in Aerostar

modifications and is closely allied with today's Aerostar Corporation, used a

number of devices - not to make the wing stall, but to ensure the control

surfaces work at these low speeds. On the back end, one problem was that the

rudder's leading edge protruded into the air stream when rotated, causing a

burble and airflow separation at low speeds. Smoothing the air and keeping it in

contact with the rudder required the installation of vortex generators, fairings

added to the rudder hinge points and small airfoil surfaces added at the fin's

base to prevent the air from flowing up the stabilizer. Piper, while working on

the same situation, added another rudder on the bottom of the plane, but this

didn't seem to be quire as effective. (Vortex generators are small airfoils,

about 1/2 X 1 inch, that are attached to the fin/wing and angled to the

fin's/wing's chord. As the air passes over and around, the airfoils induce high

kinetic energy, which decreases the boundary layer and reduces the speed at

which there's airflow separation.)

Up front, the ailerons are a Frise design, in which a small portion of the

surface sticks down into the airflow when the aileron is rotated up. When

rotated down, the surface between the wing and the aileron is smooth. This is

designed to counteract adverse yaw. At slow speed and maximum deflection, the

aileron on one side of the plane would stall. Therefore, vortex generators have

been installed on the bottom of the wing.

Subsequent testing has shown that the plane can be controlled, completely

stalled with full flaps and 90 percent power, within 15 degrees of roll and yaw,

at 52 knots, while descending at 4000 fpm.

The Model 700

Through the 1970s, Piper continued to modify and improve the Aerostar line and

announced the addition of the PA-60-700P, called the Aerostar 700P, to the line

on November 20, 1982. Design on the 700P, by Piper, had started in January 1981,

with prototype construction initiated six months later. The first flight was in

September 1981, and production began in December 1982. FAR Part 23 Amendment 6

certification was received in May 1983, and the first customer delivery was in

December 1983. The model was also certified for flight into known icing. Only 25

of these planes were built.

Prior to that, however, in 1980 Machen started producing an upgraded version of

the Aerostar 601P. Called the Superstar II, or Super 700, its engines were

replaced by TIO-540 engines with Garrett TA-18 turbochargers and induction air

intercoolers, each rated at 350 horsepower and driving a Hartzell three-blade

propeller. Robyn Astaire's plane, N40X, was a Piper-built 602P that was

transformed into a Super 700 Aerostar by Aerostar Aircraft/Machen Inc.

The Piper version, if indeed there was nay difference at all, of the Model 700

sported a pair of intercooled, flat-six, counter-rotating, 350-hp Lycomings,

TIO-540-U2A engines. The plane's cruise speed increased to a reported 261 knots

(mid-cruise weight and optimal altitude), with enough capacity in the turbo

system to maintain power and cabin pressure to 25,000 feet. The single-engine

ceiling is 16,500 feet, which will get you over all the dirt here in the lower

48.

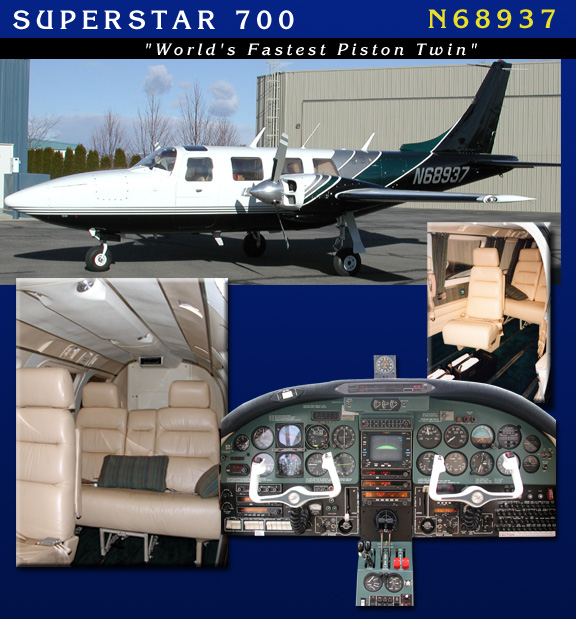

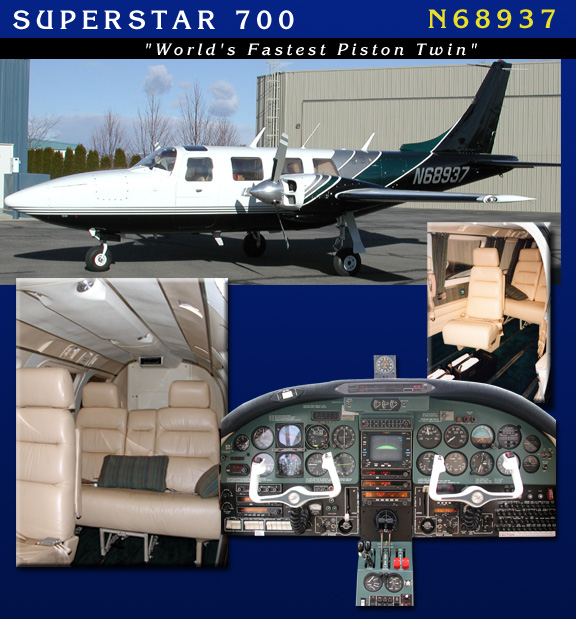

But the power plants are only part of the picture, as we were to discover upon

examining Astair's 700P. Shining in the sunlight, the plane's paint scheme is

tastefully designed. In fact, Astaire is so proud of the design, she said

there's a design patent on the colour and scheme. While the fuselage's breadth

appears to be small, the interior is surprisingly commodious. Entry to all the

seats is through a clamshell-type door located at the pilot's seat. With the

pilot's seat all the way forward, entry is easily accomplished. Putting the only

door at the pilot's elbow takes the term "a pilot's plane" to a new level,

especially in an emergency. Lest anyone think this callous, there's an emergency

exit above the wing on the starboard side.

Astaire's plane is as luxurious as one could imagine, with leather, carpeting

and a tastefully done decor. Her seating arrangement is a pilot, copilot (not

required) and up to four passenger seats with a center aisle. Once inside and

ensconced in the copilot's seat, I found all the instruments easily within view

- and there were quite a few items to see. The almost entirely King avionics

assembly includes a pair of KY196 coms, two KNS 81 RNAV receivers, a KLN 88

loran, a Trimble 2000 GPS (used for IFR approaches), a KN 64 ADF, all of which

are feeding into a colour King EFIS centrally mounted in front of the pilot

seat. To round things out, there's a cluster of JPI engine instruments on the

right sidewall. We bemoaned the fact that we weren't able to view all this at

night, because Astaire said the colors on the panel are outstanding.